Choosing the proper packaging for your products may seem daunting for a business owner. Thermoformed packaging can offer a multitude of benefits, from providing increased protection and excellent durability to aiding in the marketing of your items. However, with the range of options available, which type of thermoformed packaging should you select? Discover some key factors to consider when choosing the ideal thermoformed packaging for your business.

Design and Aesthetics

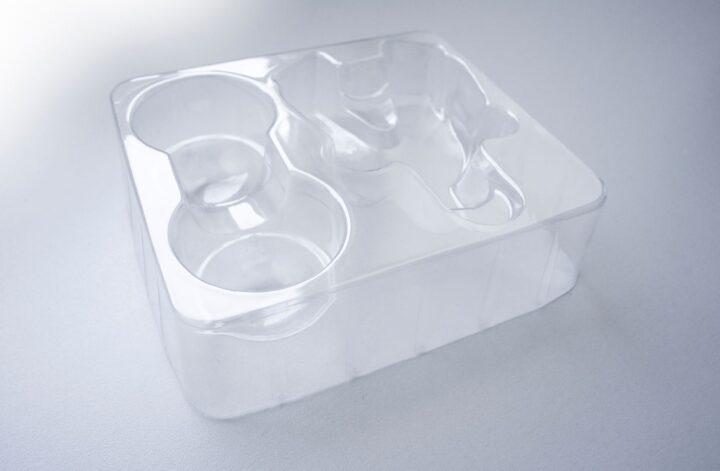

One of the primary considerations when selecting thermoformed packaging is the design and overall aesthetic appeal. Visual appeal helps to grab a customer’s attention and ensures your product is memorable. Depending on the nature of your products, you may choose from various types of thermoformed packaging designs, such as vacuuming forming or plug-assist forming. Each type of packaging adds different levels of protection, display options, and ease of use that can influence your packaging decision.

Material Selection

The type of material you select for your thermoformed packaging can play an essential role in its functionality, sustainability, and cost. Some common materials used in thermoformed packaging include:

- PVC (Polyvinyl Chloride)

- HIPS (High Impact Polystyrene)

- PP (Polypropylene)

- PET (Polyethylene Terephthalate)

- rPET (recycled Polyethylene Terephthalate)

Your choice of material should provide a balance between product protection and eco-friendliness, ideally utilizing recyclable or biodegradable options to minimize environmental impact while maintaining the desired level of durability.

Budget Considerations

When choosing thermoformed packaging, it is vital to consider the various factors contributing to overall costs. Key components include design complexity, production run size, material choice, and any additional features, such as printing or labeling. Striking an appropriate balance between cost and quality ensures that your packaging will efficiently protect and display your products while helping your business maintain a healthy profit margin.

Ease of Assembly

The ease of assembly for your packaging solution is another vital aspect for consideration. Packaging that is too difficult to assemble can hinder productivity and cause delays in fulfilling orders. Select thermoformed packaging designs that minimize assembly time while providing your products with the necessary protection and display options.

Customization and Adaptability

Many different products require unique packaging solutions, particularly if they vary in size or shape. When selecting thermoformed packaging, consider choosing a provider that offers customization options to suit your specific requirements. The flexibility to adapt packaging to your needs will help accommodate your product demands as they change or grow.

Selecting the perfect thermoformed packaging for your business requires careful consideration of design features, material selection, budget constraints, ease of assembly, and customization options. By keeping these factors in mind, you will find the ideal packaging solution that helps your products shine on the shelves.